Nakilat brings in energy efficient ME-GI LNGC newbuild into its world’s largest LNG fleet

New Nakilat-Maran Joint Venture Company Announced

In March 2019, Nakilat announced that it will be adding four (4) more LNG carrier (LNGC) newbuilds through a new joint venture with long-term partner Maran Ventures, the LNG ship-owning arm of the Angelicoussis Group. Under the deal for the new joint venture (JV), Global Shipping Co. Ltd. – Nakilat holds a 60% stake, while Maran holds the remaining 40%.

The four (4) modern LNG newbuilds are equipped with some of the most advanced technology in the market today, with two of them featuring ME-GI, and the other two X-DF propulsion systems. The two ME-GIs and the two X-DFs have a large cargo carrying capacity of 173,400 cbm and 174,000 cbm respectively.

Two (2) newbuild ME-GI engine LNG carriers are set to be delivered in 2020, and the next two (2) newbuild LNG carriers in 2021. This will bring Nakilat’s fleet to 74 vessels, which is just under 12 percent of the current global LNG fleet in carrying capacity.

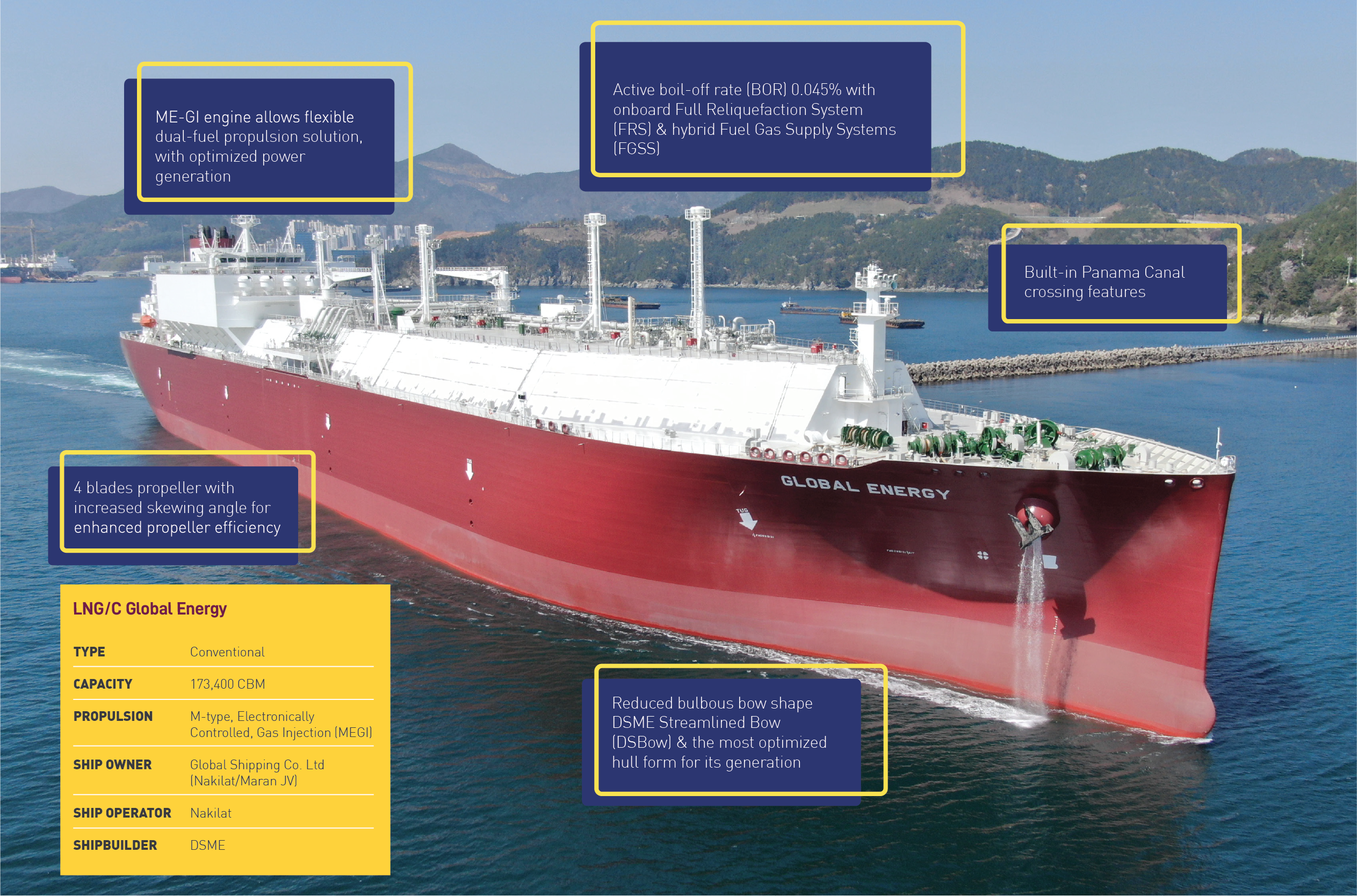

Global Energy, first ME-GI type LNGC newbuild for Nakilat

In May 2020, Nakilat’s very first M-type, Electronically Controlled, Gas Injection (ME-GI) engine LNG carrier newbuild was successfully delivered to the Nakilat-Maran JV, Global Shipping Co. Ltd.

The first delivery of the 4 LNG carrier newbuilds, Global Energy, was built by Daewoo Shipbuilding & Marine Engineering (DSME) in South Korea, with cargo carrying capacity of 173,400 cbm and equipped with the most advanced technology in the market today.

LNGC Global Energy is commercially managed by Nakilat and technically managed in-house by Nakilat Shipping Qatar Limited (NSQL), a ship management subsidiary of Nakilat.

Salient features of LNGC newbuild 'Global Energy'

The ME-GI series of LNG vessels such as Global Energy are designed to be significantly larger than the conventional LNG carriers with lower boil-off rate (BOR), more fuel-efficient, and have lower emission levels than other engines currently being used in LNG shipping. Furthermore, operating a ME-GI class LNG carrier is also said to have considerable capital expenditure and overall operational cost savings – one of the most competitive LNG carriers on a Unit Transportation cost (UTC) basis.

These are among the improved design features of the vessel, geared towards better energy efficiency and reduced environmental footprint:

- ME-GI engine allows flexible dual-fuel propulsion solution:

- M-type Engine (ME) fitted with exhaust gas recirculation (EGR), to reduce formation of nitrogen oxides (NOx)

- Optimized dual-fuel power generation:

- Active Emissions (AE) control fitted with Selective Catalytic Reduction (SCR), the most efficient method to reduce up to 90-95% of NOx emissions

- Onboard proprietary Full Reliquefaction System (FRS) and hybrid Fuel Gas Supply Systems (FGSS)

- 4 blades propeller with increased skewing angle for enhanced propeller efficiency

- The most optimized hull form of its generation with reduced bulbous bow shape – DSME (DSBOW), offers wider range of optimized speed

- Built with Panama Canal crossing features

PREVIOUS Q-MAX ME-GI CONVERSION

Driven by its sustainability focus in the aspect of environmental management, it is worth noting that Nakilat pursued a pilot project for the world’s first ME-GI systems onboard the largest type of LNG carrier ever built, a Q-Max. The 266,000 cbm LNGC Q-Max Rasheeda was built in 2010, one of the 45 Q-Max and Q-Flex types and owned by Nakilat.

LNGC Q-Max Rasheeda becomes the world’s first low-speed marine diesel engine to be converted to use LNG as a fuel.

It became a pivotal case study for ships of its scale.

There is no doubt that learnings from this pilot project will pave way for greater enhancement for greener shipping system designs.

Driving sustainability across its fleet

The new generation LNG vessels are not only going to be more powerful; they will also be designed to achieve greater thermal efficiency and therefore, more environmentally friendly and cost effective operations; as companies see the need to respond to an increasingly competitive marketplace that demands operational sustainability.

To meet the growing energy transportation needs in a responsible manner, the company’s fleet of LNG carriers is fitted with modern and sustainable technology, and comply with the highest international operating standards. Nakilat’s vessels have been conferred the Green Award to certify their ‘extra clean and extra safe’ operations by the Green Award Foundation.

Safety enhancement, vessel reliability and cost optimization continue to be Nakilat’s main drivers for operational excellence in managing its modern vessels. The company aspires not only to be the leading LNG shipping company, but also recognized as a safe, reliable and efficient ship operator. The new additions of more sophisticated LNGC newbuilds to the existing fleet not only gives the company a competitive edge, but also allows Nakilat to provide additional capacity and flexibility to its valued customers.